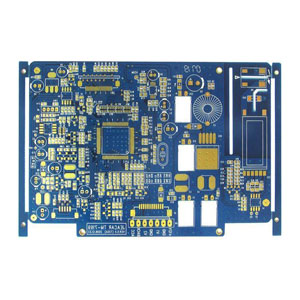

Product Detail:

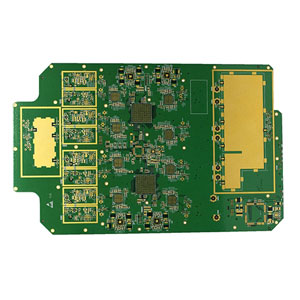

Generally speaking, multi-layer PCBs are used for more complex devices, but 1 or 2 layer PCBs are used for simple devices. Undoubtedly, electronic engineers prefer to choose a multilayer PCB because it can provide high signal strength. A 2-layer PCB is the most common of all PCB types because it can accommodate interconnections on both sides. Therefore, we will explain the difference between a 2-layer PCB and a 4-layer PCB, and how to choose the right type for your project.

PCBLike established in 2012, has mainly produced single, double and Multilayer PCB more than 10 years. Also, we can help customer do PCB assembly and provide one-stop service. Whether it is SMT assembly, surface mount assembly, or circuit card assembly services that you are looking for, we at PCBLike have and specialize in the entire range of printed circuit board assembly services. PCBLike uses international advanced circuit board equipments and employs specialized talents for managing. Productions are exported to Europe and America, southeast Asia, England, America, Russia and other countries.

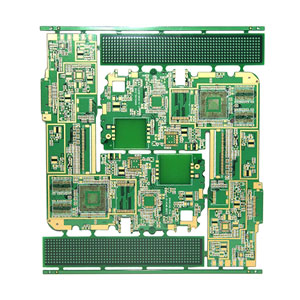

Cutting —> Inner Layer —> Layer Stack —> Drilling —> Sinking/1ST Copper Plating —> Layout —> 2nd Copper Plating —> Etching —> Solder Mask —> Legend Printing —> Immersion Tin (or Immersion Gold) —> CNC Routing —> V Cut (some boards do not need this) —> Flying Probe Test —> Vacuum Packaging

Multilayer immersion gold board production process:

PCBLike.com

PCBLike.com